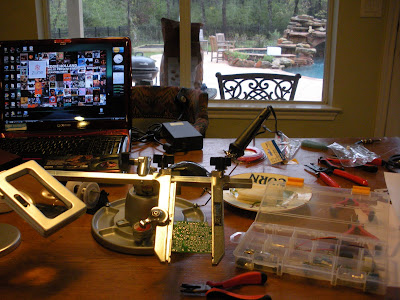

Above is the workspace I am using today.

A lot of folks think that they need a special place to work. In fact this can frequently become an obstacle to attaining some long desired goal. We can can become bogged down believing that if only I have the perfect music room/workshop/study/garage/tools I will be able to write that perfect song/build that doohickey/novel/classic car. This is (mostly) bullshit. Stephen King wrote his first novel in his laundry room, JK Rowling wrote in coffee shops, Piers Anthony does all his first drafts on yellow legal pads, Sargent Pepper was a 4 track album, and some of the most beautiful art and scuplture has been produced without the least access to modern tools and chemistry. Most important is the desire to succeed.

In my case I am living an itinerant lifestyle until summer. My home is rented out and I am waiting until summer to buy a new place. So every tool I own is in a box somewhere. To make this kit I needed to use only tools I could buy inexpensively or could borrow.

The most important item is something to hold the circuit board. This is something I couldn't borrow and was the most expensive item to buy. Since I don't already own one it was not a foolish expense but at $70 was the most expensive single item. It is a Panavise model 324 electronic work center. After having used it I would say that the most useful feature is the parts tray base and the board holder. But they are also expensive enough by themselves that even if you throw away the soldering iron and solder roll holders it would still be cheaper than buying the pieces separately.

The next most important item is the soldering iron. For electronic work you want something in then 25-30 watt range. I chose a Radio Shack 15/30 watt switchable. Would have preferred a Weller Iron but when I went to Fry's the soldering iron section looked like it had just been visited by the Huns the only stock on hand were some very sketchy chinese irons and a few Weller Irons that were simply too large. I bought nothing and left most dissatisfied. Instead I reluctantly went down the street and spent $50-60 at Harbor Freight and another $60 at Radio Shack.

The other items are all fairly basic hand tools that can be pruchased almost anywhere. For the most part they were purchased at Harbor Freight. Although cheap they seem to be ok except for the lighted magnifying glass. It is simply too heavy to be supported by the neck joints of the neck.

Solder and the specialized soldering tools are Radio Shack. I prefer silver solder it creates a better contact and just seems to work better for me. Plus it's just not that much more expensive. The only draw back is that the sizes available were very fine and that makes it a little more difficult to work with.

Finally the space is the kitchen table at my brothers house. (Don't tell his wife) Convenient to the bathroom, refrigerator, and 4 dogs who all like to demand attention when delicacy is required.

This is Sailor.

This is Sailor.

Well there you go. The thing itself completed.

Well there you go. The thing itself completed.

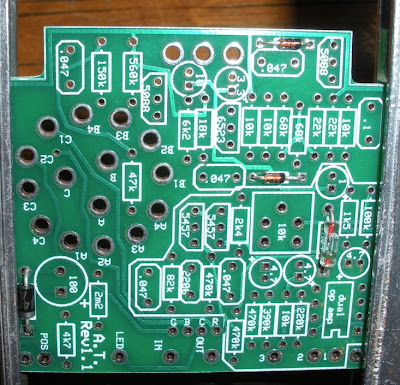

This is the board. The first step in assembly is to populate it with components. The directions aren't 100% clear but seem to indicate soldering components after each component type is placed in the board. This view shows the first step with the diodes in and ready to be soldered.

This is the board. The first step in assembly is to populate it with components. The directions aren't 100% clear but seem to indicate soldering components after each component type is placed in the board. This view shows the first step with the diodes in and ready to be soldered.